Mon 3 Oct 2011

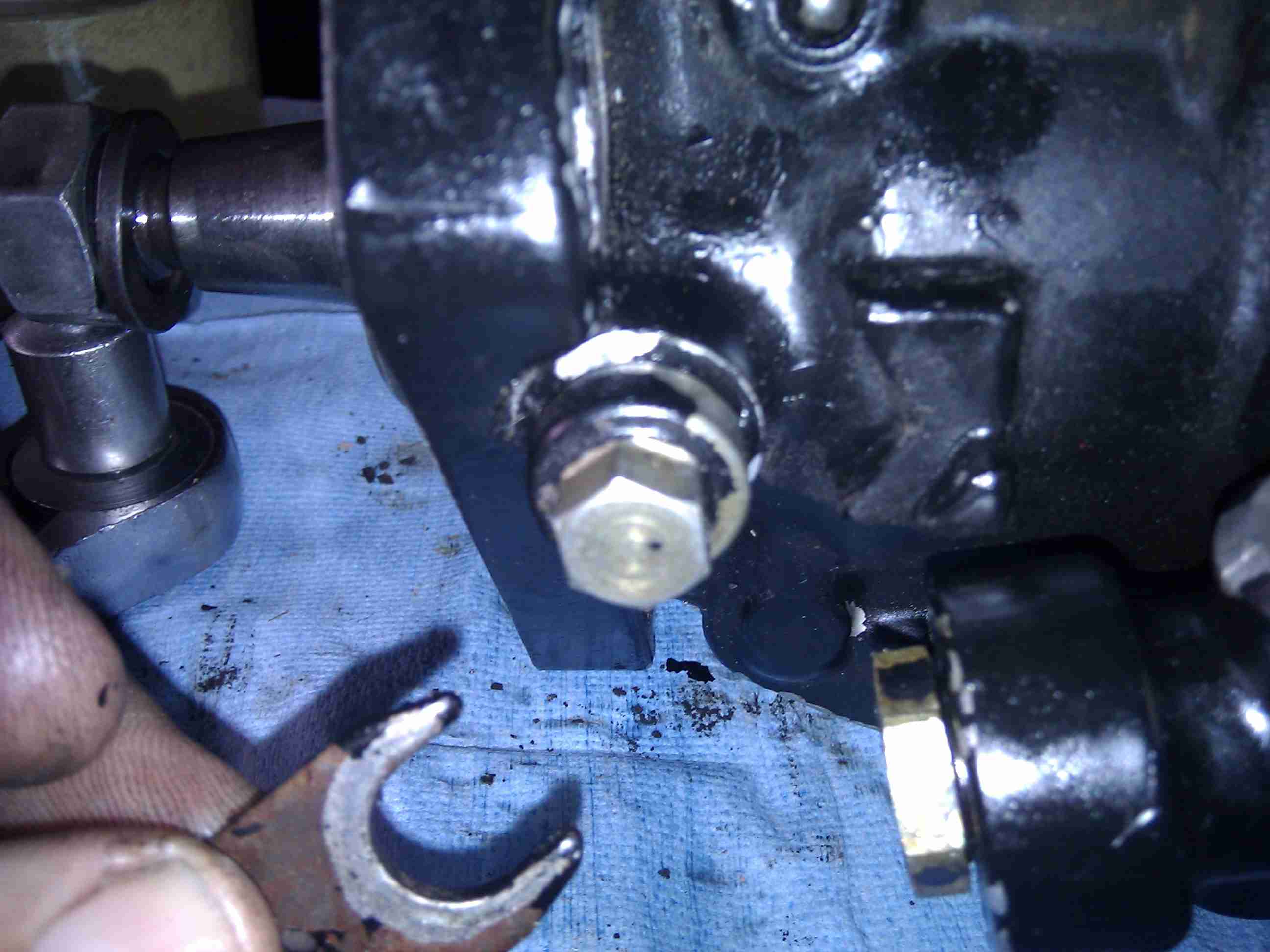

I installed new orings as soon as I got the control valve apart. That way I didn’t mix up any orings with other assemblies.

This control valve head takes only a 10mm wrench. It was very tight. So I had to use some leverage to get it free.

Here are all 4 o-rings on the control valve. This also shows the orientation of the parts. The governor shaft seal is installed but is still waiting for it’s washer and jam nut.

Control valve with o-rings removed without adding any scratches.

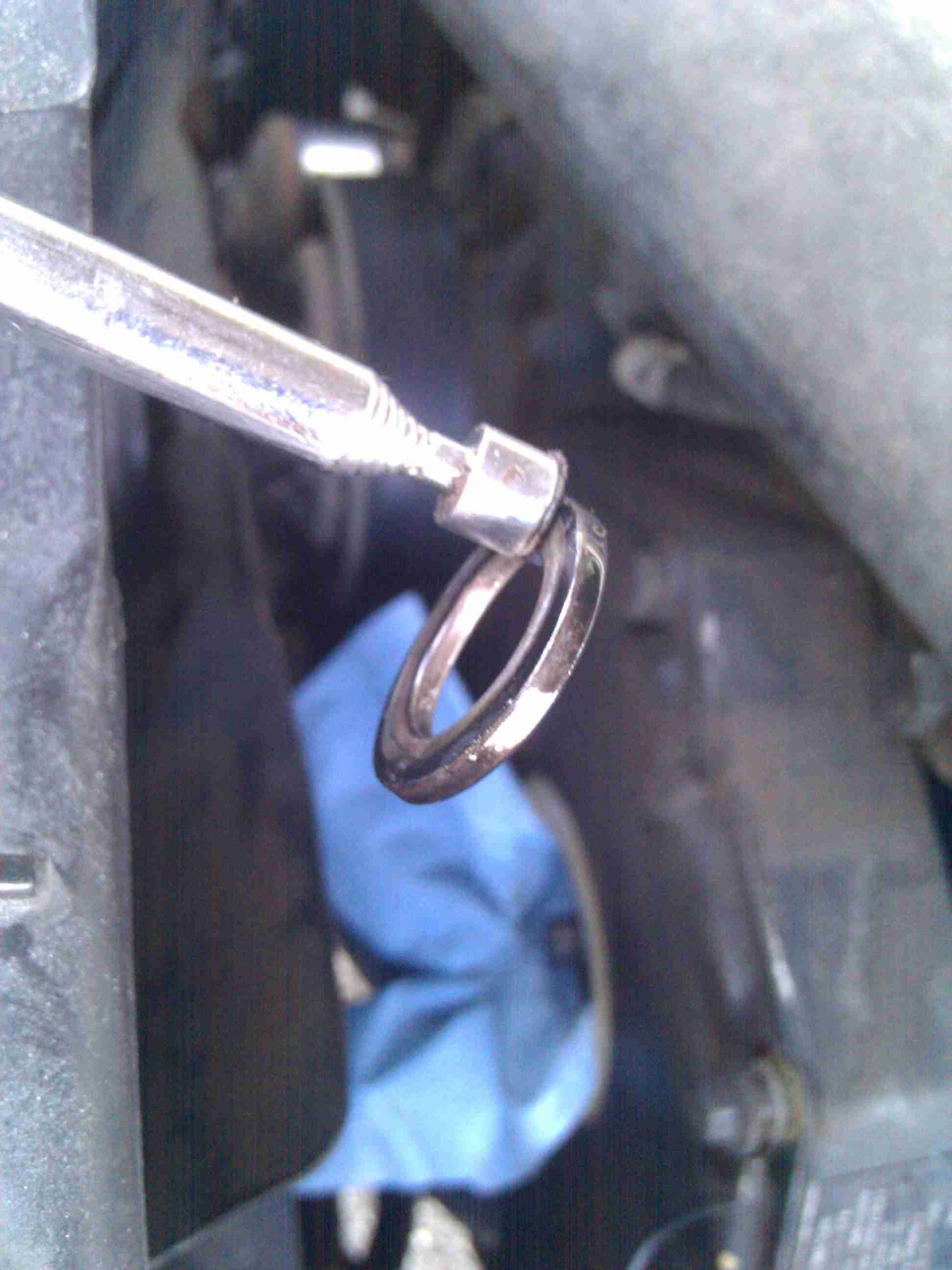

The control valve had 3 parts loose when I took it out of the pump body. In this pic I installed the spring and piston into the control valve. The only thing remaining was this clip. It seems like it would be a press fit.

I hope this is how the control valve parts go back together. I used a magnet to pull them out of the bore the control valve screws into.

No place for the spring and piston to be held in the cavity that they came out of. It must mean that the parts are held in the control valve with the circular clip.