Wed 5 Oct 2011

Part 8 – Throttle Limit Screw

Posted by Administrator under Bosch VE Pump , Throttle Limit ScrewNo Comments

This is a warranty cover for the throttle arm limit screw.

It finally took using some large dikes to cut the cover off. It had a nut inside of it that I turn the cover back and forth to get it off.

Must measure the adjustment screw so it goes back to the exact same position when I’m done. .486″ is the measurement.

Here is how I actually took the measurement.

Here is the reason all of this work had to be done. Access to this allen screw was not good enough since the screws are so tight on the pump.

All better now. Time to clean all around the perimeter before removing the top porting of the pump.

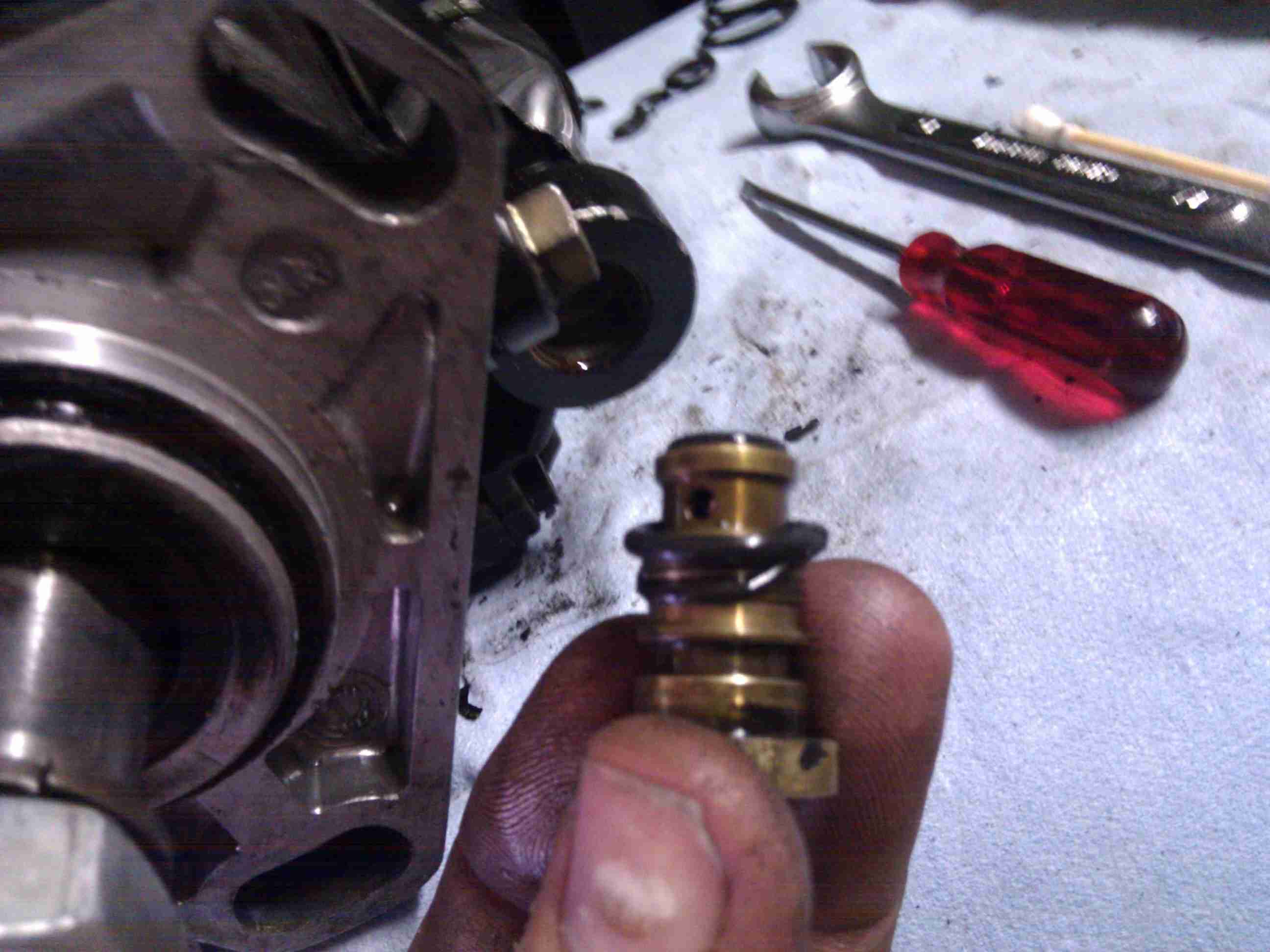

Once the 4 allen screws are out, here are the internals. That spring is the speed governor for the Cummins diesel engine. Stock it’s set to 2800-2900 rpm. This spring is labeled 366 which is for 3200 rpm. Someone added it before I owned it. Didn’t notice it would rev that high as I don’t push the truck at all.

Just remove one end of the spring from the upper part of the pump and set it aside. The spring and top hat assembly can be lifted straight up and removed.