Wed 12 Oct 2011

The pump is back in. Runs better. Way more power. No gray smoke at idle. But some off idle through full throttle.

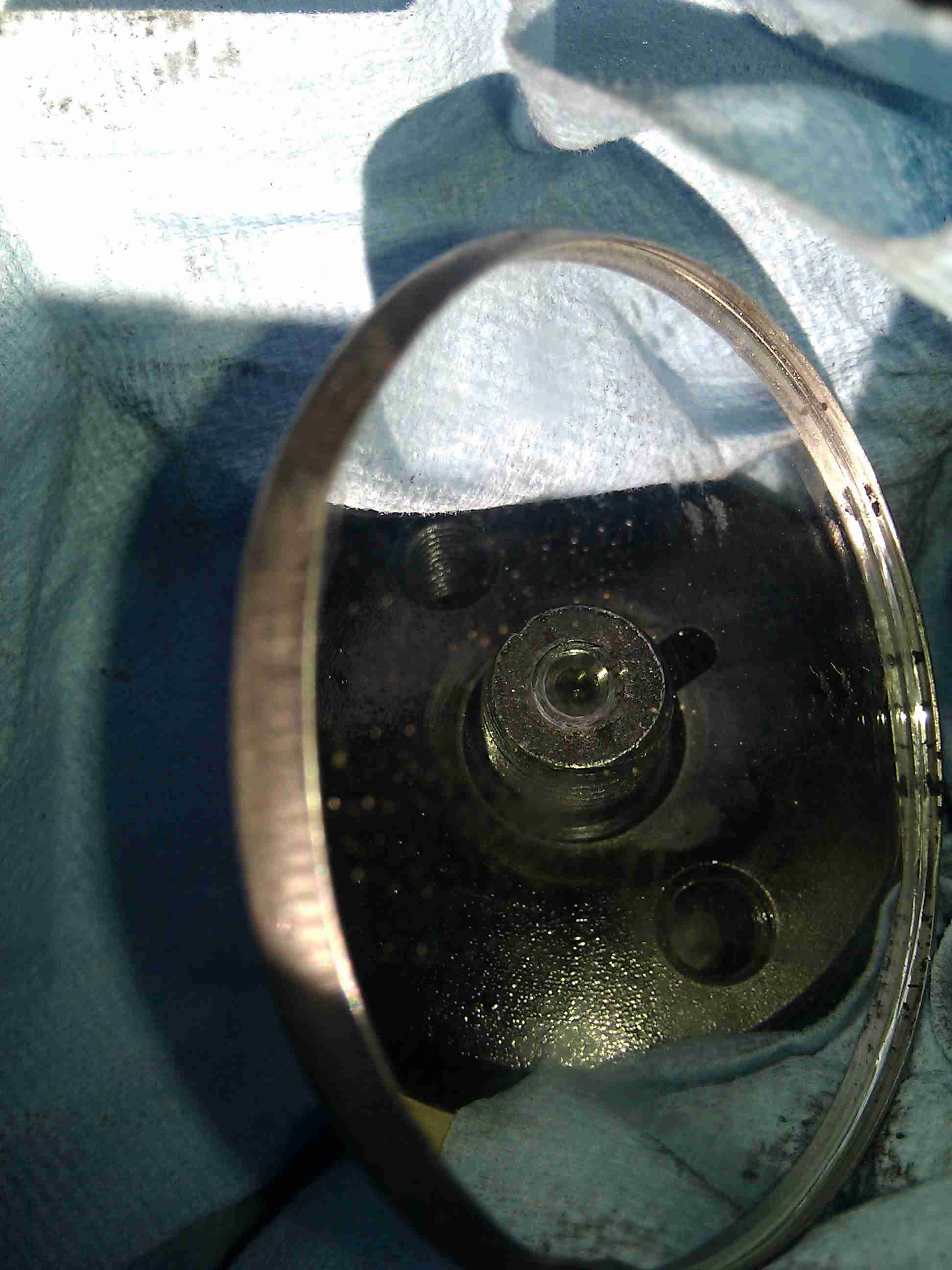

First pic is how I verified that the key was in the gear’s slot. You can see the very end of the key nearest to the shaft. The key only sticks up barely 1/16″ above the shaft. Doing this gave me far more confidence.

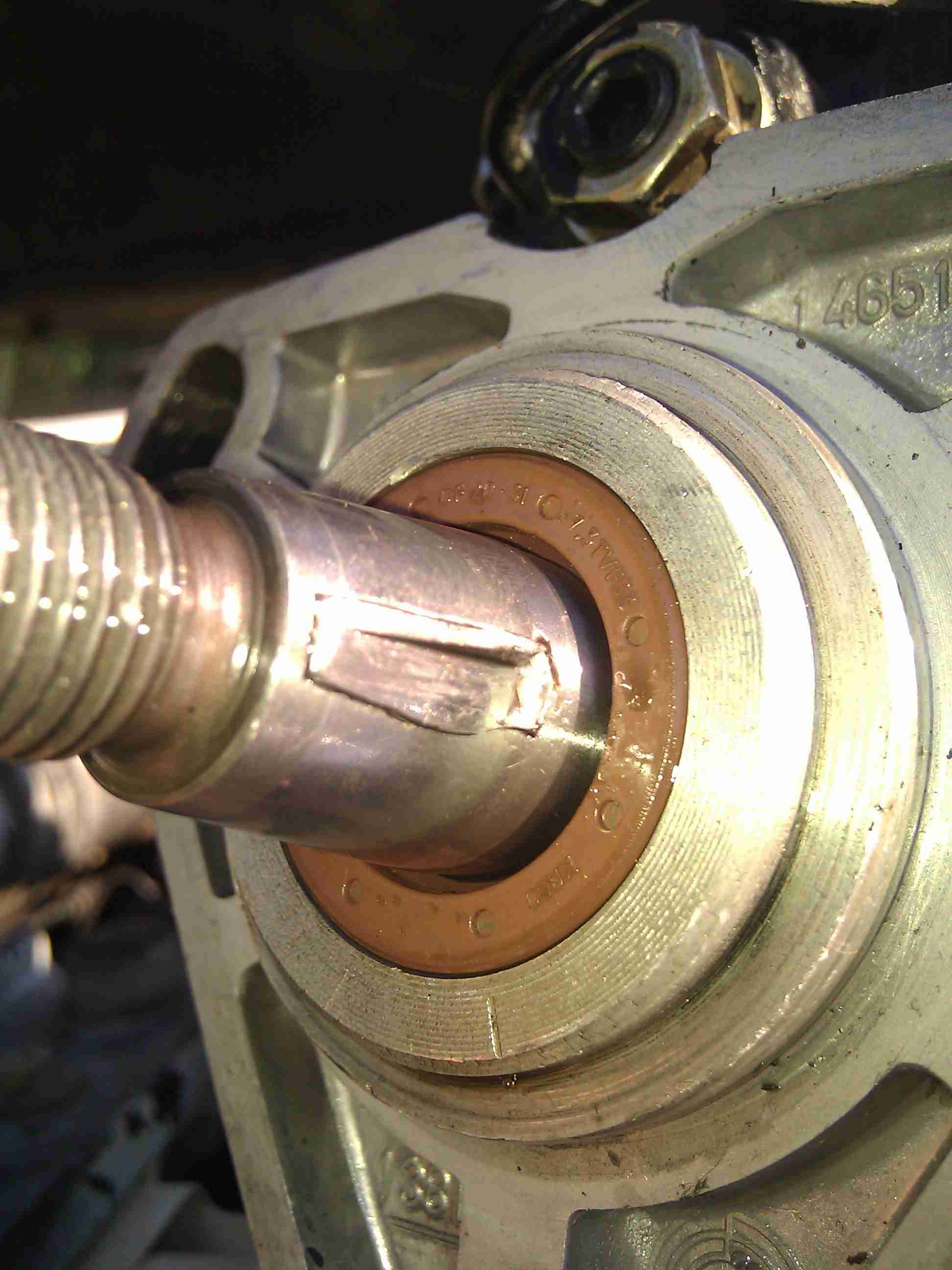

When I was torquing the nut on it didn’t feel so mushy going on. Here’s another hint. The threads of the pump stick out past the nut about 1.5 threads worth. The shaft was flush with the nut when the key got mushroomed.

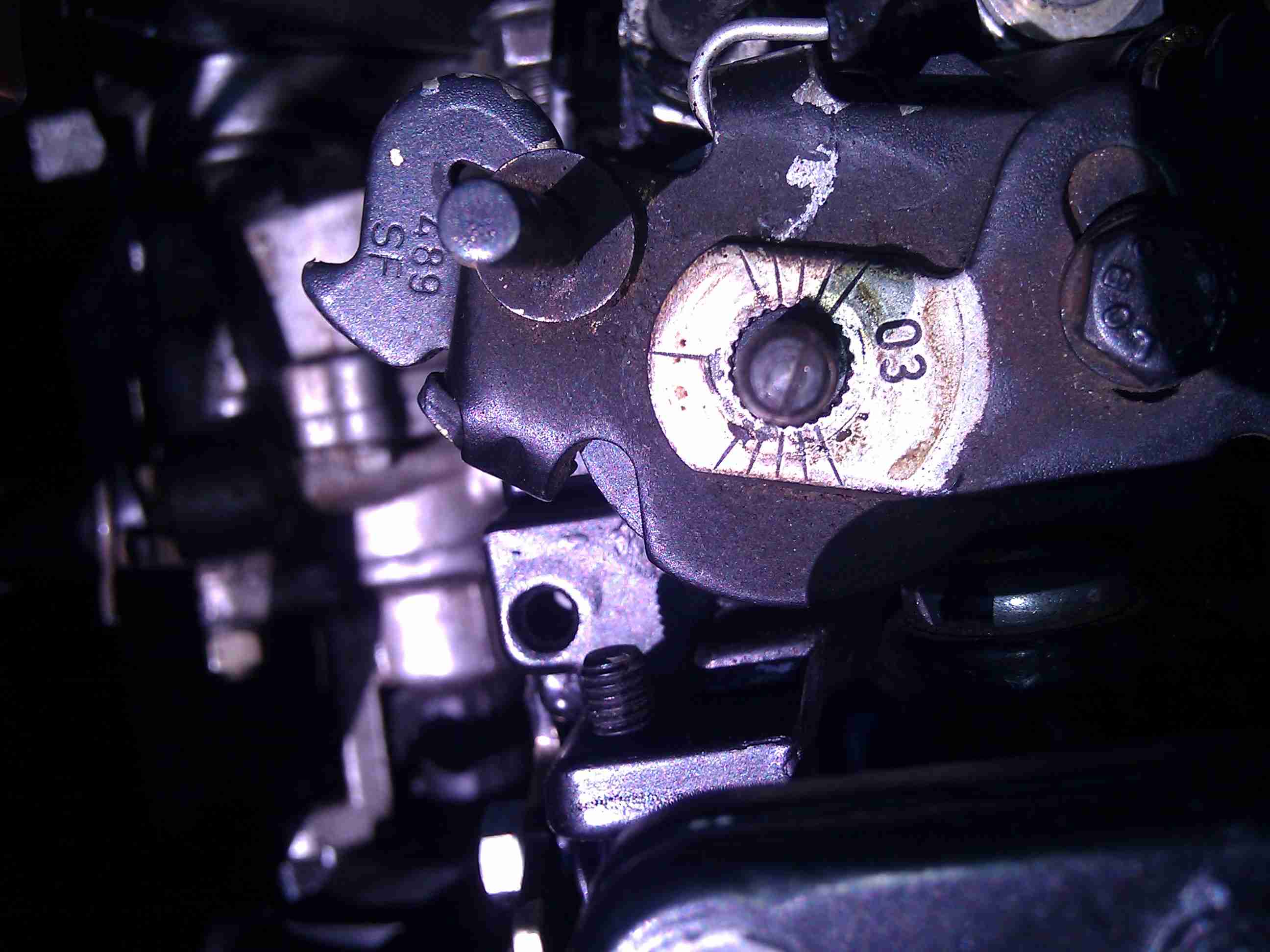

The far left key is the new one from Cummins. The middle one is the one that got mushroomed. The right one came from the hardware store. The new one and the middle one both have a deep mark in the middle of the key. This distorts the keys slightly so they both are a tighter fit! This keep them from falling out during pump install.

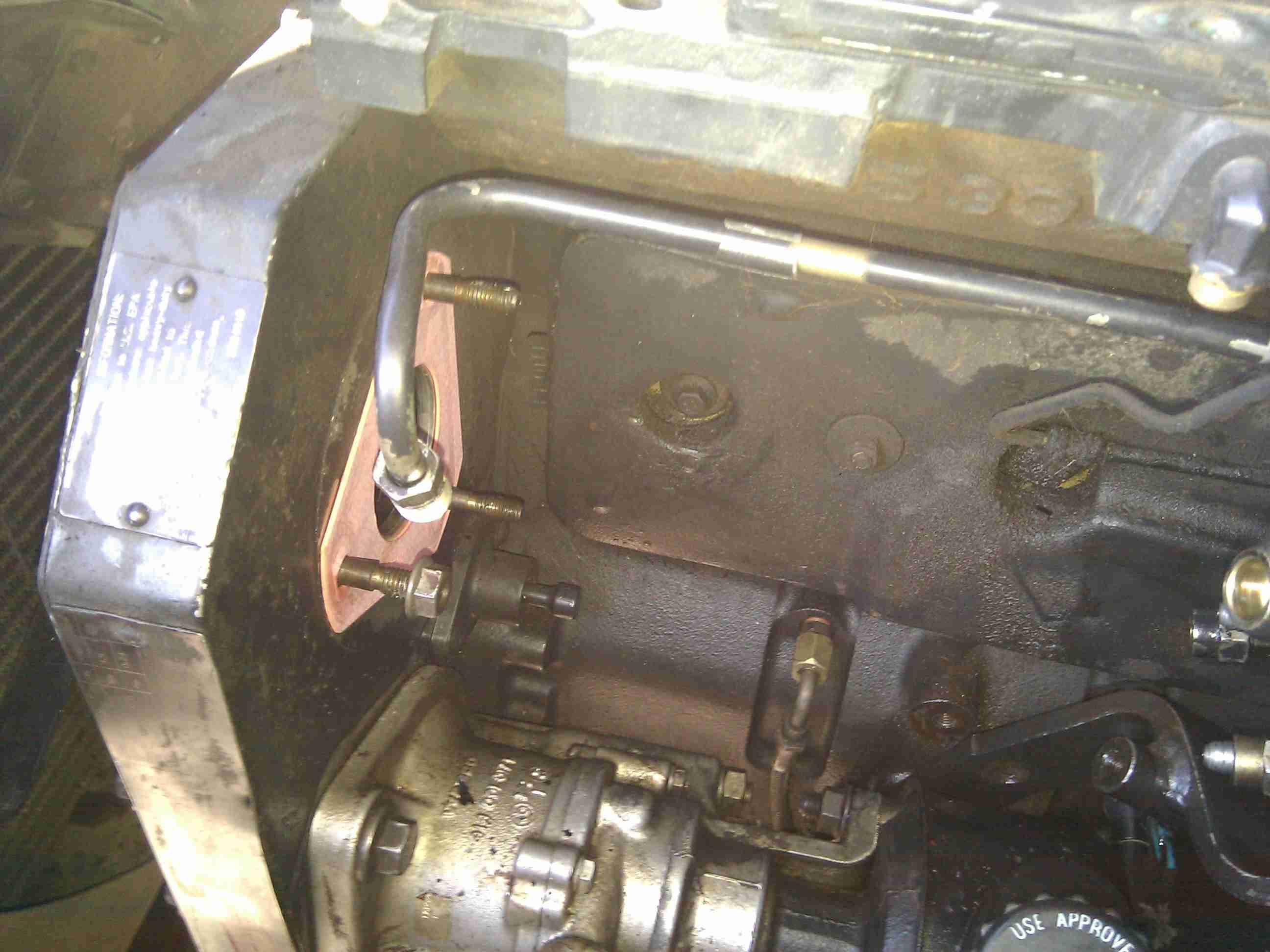

As for the smoke. If I understand correctly my timing is still a bit retarded causing excess unburnt fuel. The pump now looks a bit more advanced than it originally was. This first pic is where the pump timing is set now.

This second pic was the pump timing when I received the truck.